Why does rebar break and not bend?

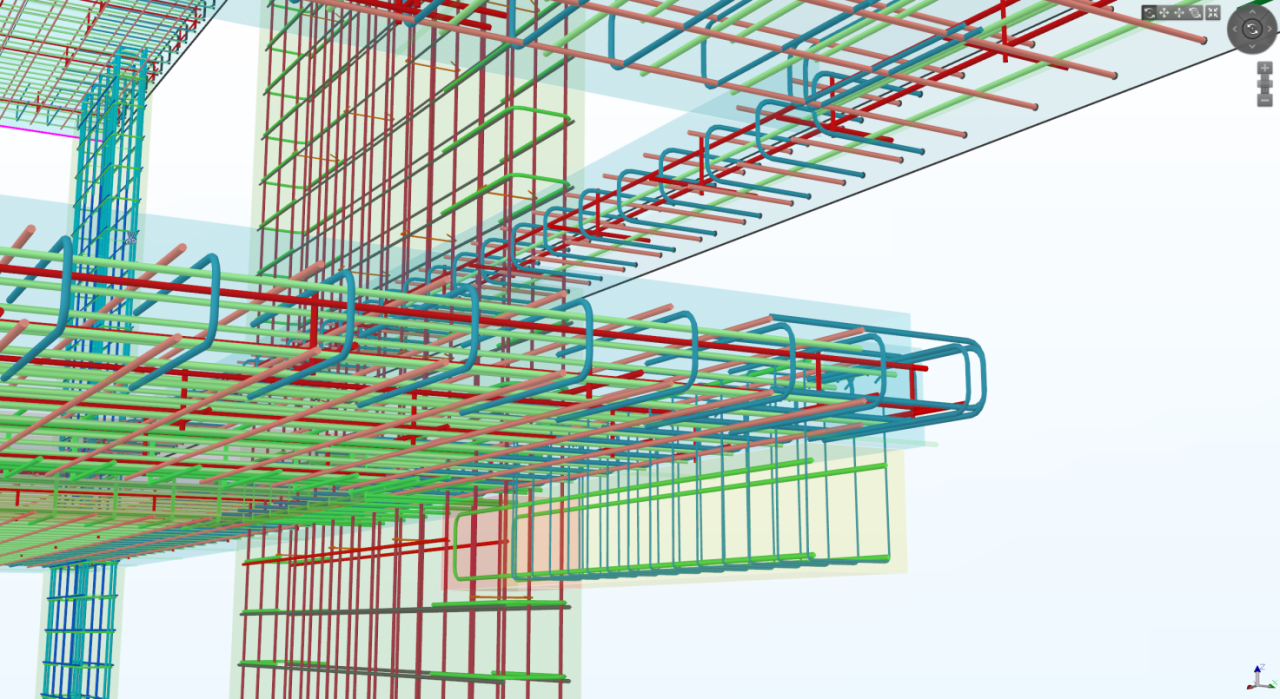

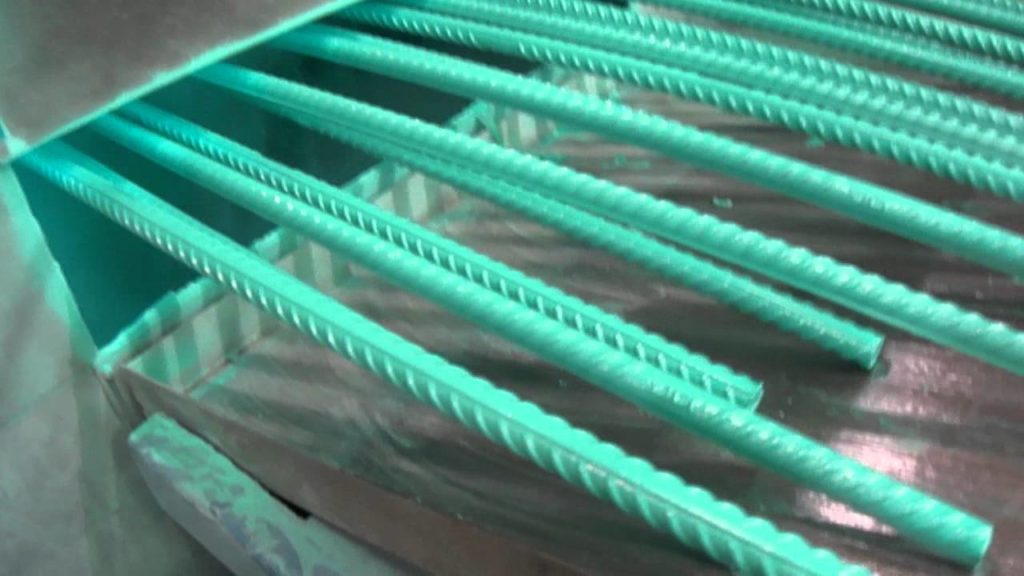

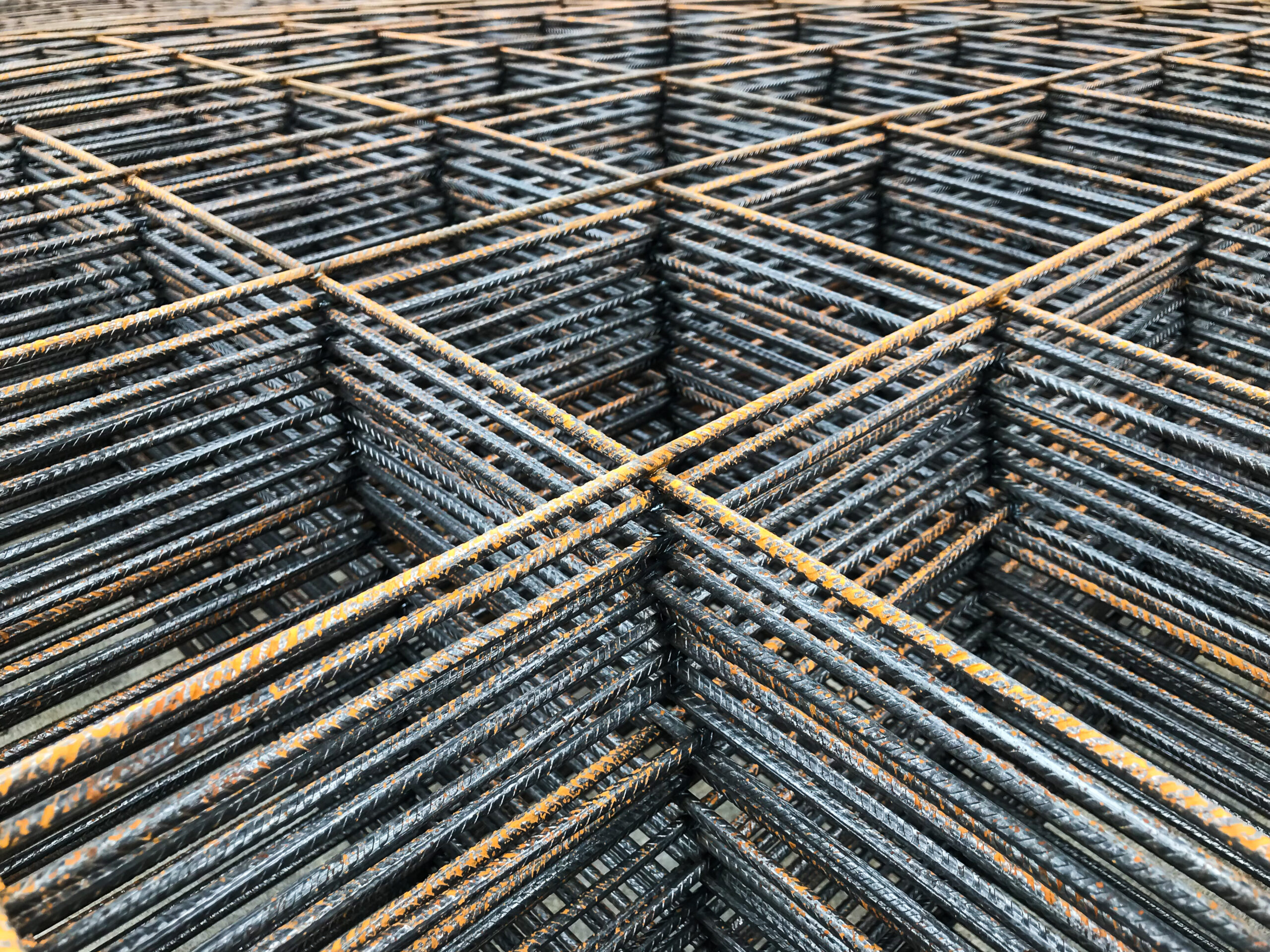

Why does rebar break and not bend? Rebar is the short form of reinforcing bar. It is also known as reinforcing steel or reinforcement steel. Rebar significantly increases the strength of the structure. Rebar’s surface is often deformed to promote a better bond with the concrete. There are different types of rebar.

On the off chance that Rebar is breaking when you bend it, It seems that you presumably have a second rate steel combination, with a wide range of different metals in there to make it less expensive. Or then again maybe you’re attempting to twist it without a previous to give it the base range it needs? Other than that, everything I can consider is that a high elastic steel may wind up weak because of work solidifying when it was first fixed and afterward bowed once more. High elastic steel (500MPa) is impressively less malleable than typical low carbon steels (275MPa). The high carbon substance makes it progressively helpless to solidifying and brittle failure.

How to bend rebar?

Construction experts refer rebar as pieces of steel that will often constitute part of the inner structure for a piece of concrete. Rebar also has other various uses. Normally, it is a long piece of steel in a stick or rod shape. If you need to bend rebar for any reason, consider the advice of experienced contractors or other experts before attempting this somewhat risky process.

Professionally bending rebar

At first understand the basic issues possible with manually-bent rebar and skill to maintain or avoid them. When you bend metal, you normally debilitate or weaken it. At the point when done effectively,you can minimize damage and still get the shape as your requirement. rebar break and not bend

- Continuously note the evaluation and size of the bar you’re bending, checking against the gear you’re utilizing to guarantee it works.

- Check with your task designer to guarantee your curves meet the insignificant inside twist measurement. On the off chance that you don’t have a clue what this is for your task, hold up until you do.

- Never re-twist rebar. When you’ve bowed it, it’s done. Persistently working it will fundamentally bring down its strength.

For more details, please visit https://rebarpeople.com/why-does-rebar-break-and-not-bend/